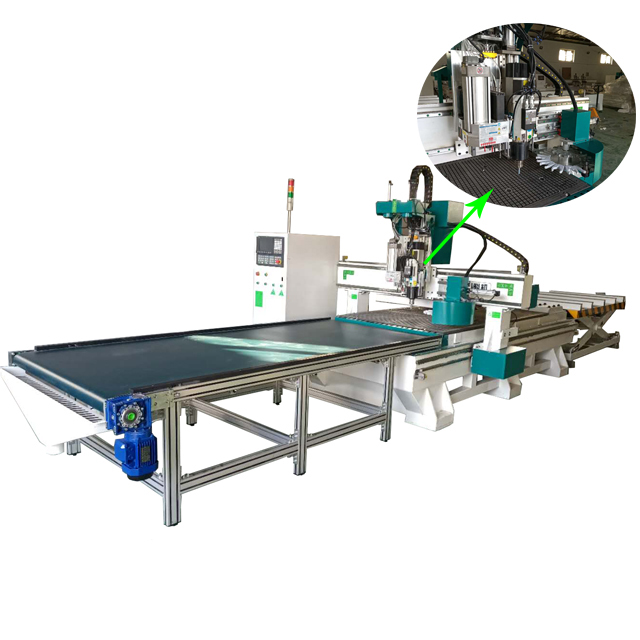

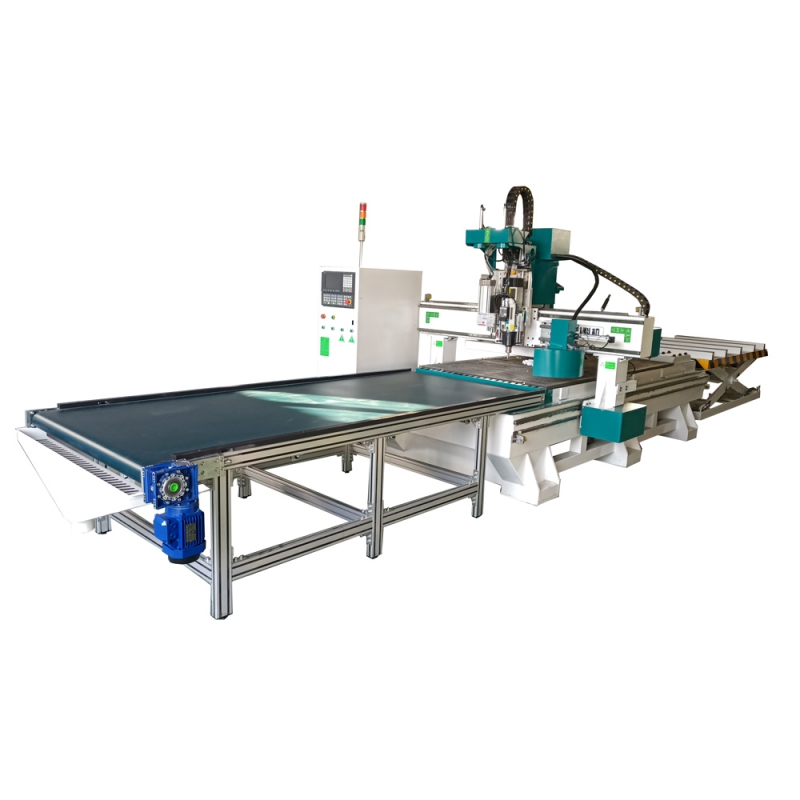

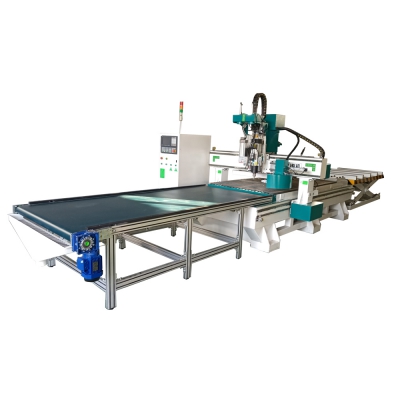

Nesting ATC cnc router

- Working area: 1300mmx2500mm

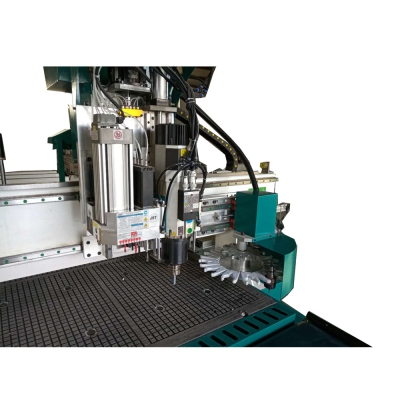

- Spindle: 9kw ATC air cooling spindle

- control system: Taiwan LNC control system

- Guide rail: Taiwan HIWIN guide rail

- Software: Ucancam / ArtCam/TYPE3

- Motor: Leadshine 1.5kw servo motor

- Machine bed: Welded with thickness steel tube

- Transmission: Helical Rack Pinion

- Table: Vacuum table

- Working voltage: 380V/50Hz, 3 phase

- Traveling speed: 30-50m/min

- Working speed: 25-40m/min

- Application: cabinet door, door making

- Inquiry

Product Description

Introduction

This machine is main for furniture industries, such as wood door,kitchen cabinet etc. The loading and unloading system also can be added to improving work efficiency.

Machine advantage

1. Our machine bed is welded by 6-10mm steel tube, processed by the lathe machine and facing machine, ensures the stability of processing.

2. The machine is finely made, with high-precision guide rail, ball screw and Japan Shimpoo reducer transmission.

3. With drilling head and alphacam software, all the steps of production are finished at one time.

4. With Leadshine 1.5kw servo motor, the working speed is more higher.

Applications

Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Send Email

Send Email annecnc

annecnc